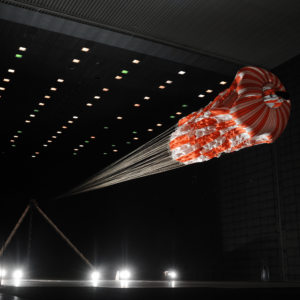

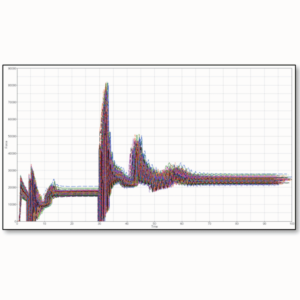

Airborne Systems’ test capabilities are unmatched in the industry. Our engineers are well-versed in all aspects of product testing, from seam and joint element testing to highly complex supersonic wind tunnel testing. Airborne Systems’ extensive experience and knowledge base ensure that tests are conducted with the precision required to validate product performance to meet federal standards.

Airborne Systems maintains dedicated test and drop facilities in several locations, enabling us to accommodate and respond to various customer requirements.

With a test history spanning decades, Airborne Systems is uniquely positioned to apply lessons learned to every system we design and test.